Description

Description:

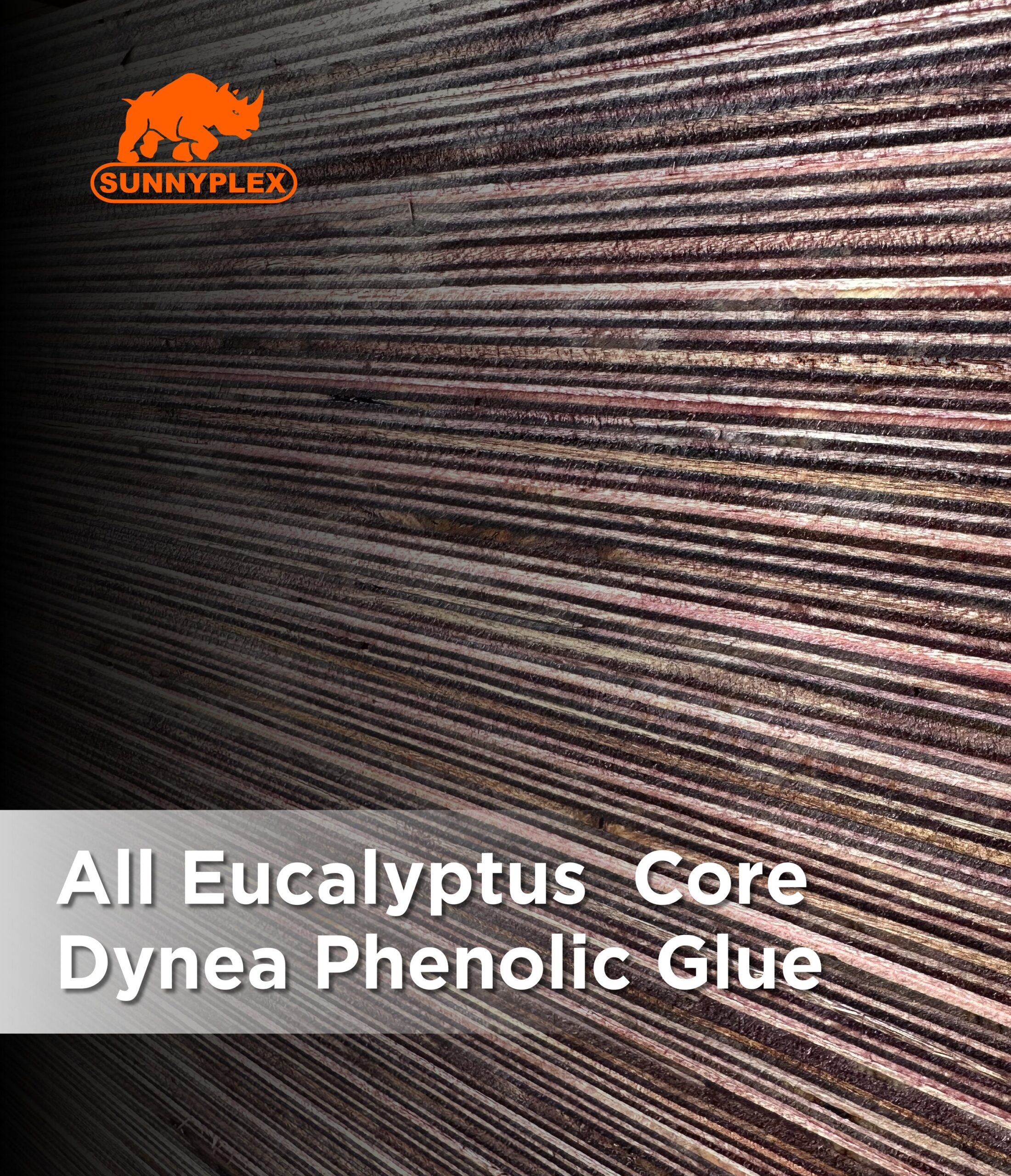

● Both sides of the board are 100% covered with DYNEA Premium Phenolic Film that reduces the porosity of the faces compared to regular boards and gives an excellent face finish to the formwork. The phenolic glue allows the board to be more resistant to moisture in formwork applications.

Characteristics:

● – Easy to manipulate

● – Easy to work using common tools.

● – Stability and high mechanical resistance to bending, traction and compression.

● – Very good weight / rigidity ratio.

Technical Recommendations for Use:

● – It is recommended to seal the edges with waterproof paint in case the boards are cut on site.

● – Use damp cloths and wooden or plastic spatula. Sharp cutting elements could damage the film and make the board vulnerable.

● – Clean and apply oil immediately before and after use.

● – Defects opened by blows, nails or other origin, must be sealed with synthetic waterproof paste.

● – Store in back-to-floor packages outside of direct sunlight and rain.

What is a “Film Faced Plywood”?

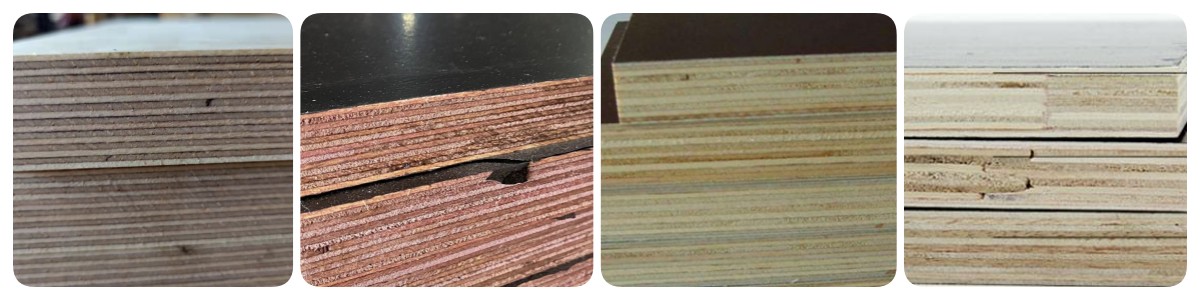

Film faced plywood or Phenolic Board or Formply or Shutterply or Marine Plywood, is the special plywood with two sides coated with wearable and water proof film. The film is adhesive impregnated paper, which are different from melamine paper overlay. The function of the film is to protect the inside wood from moisture, water, weather and extend the plywood’s service life. Film faced plywood is for outdoor use only and are most widely used as the concrete formwork panels.

| Length | 2440-6000mm |

| Wide | 1220-2000mm |

| Thickness | 4mm-35mm |

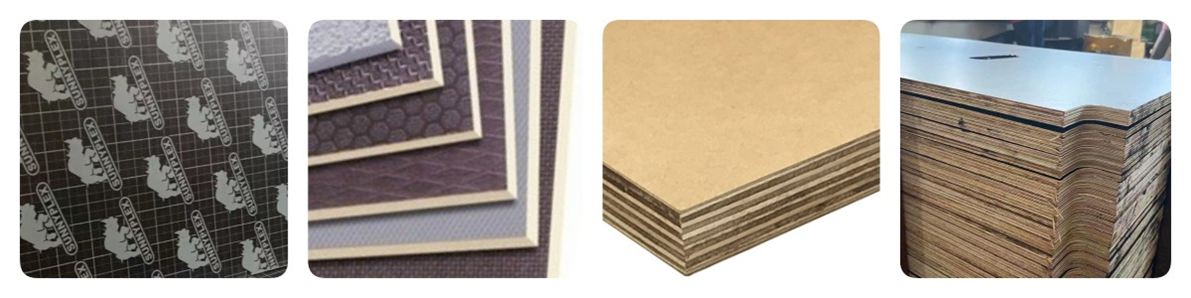

| Face & Back | With Logo / Smooth / Anti-Slip / MDO / HDO |

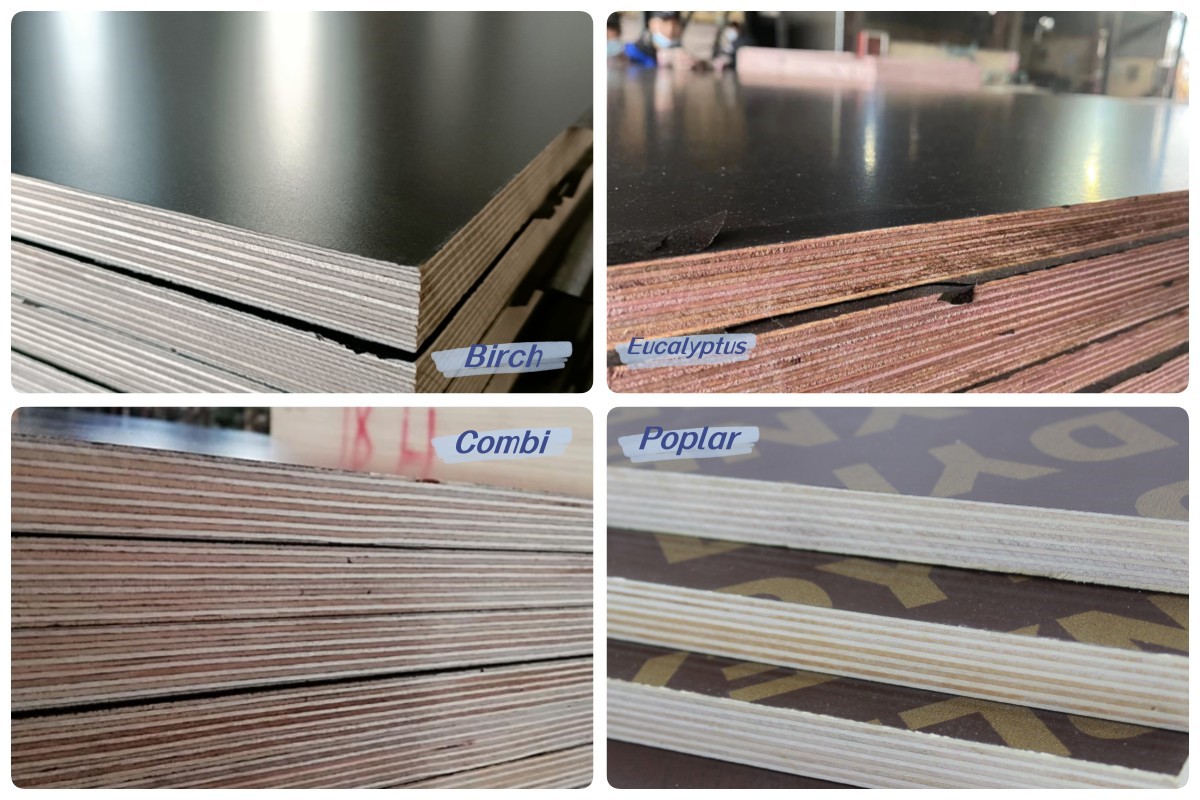

| Core | Poplar, Birch, Eucalyptus / Recycled Joined core |

| Logo | According to Order ( more than 5 containers will free) |

| Min-qty | 1*20FCL (22CBM) |

| Moisture | 8%~12% |

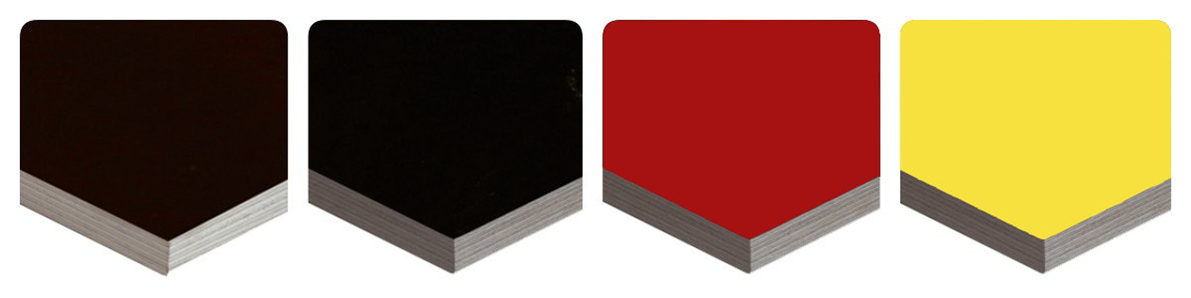

| Film | Brown / Black / Red / Yellow / Grey or Requested |

| Glue | MR / Melamine (5-24hours) / Phenolic / E0 / E1 /E2 |

| Delivery | 2 weeks (less than 5 containers) Out-putting:3000cbm/month |

Email:

Email:  Whatsapp:

Whatsapp: